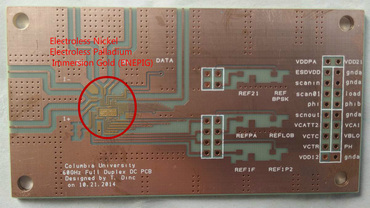

Do you know what ENEPIG is in PCB? What is ENEPIG?ENEPIG-Electroless Nickel Electroless Palladium Immersion Gold is a surface finish for Printed Circuit Boards.ENEPIG works well with lead free and conventional eutectic solder alloys.This is the best way for gold wire bonding. Advantages for ENEPIG:

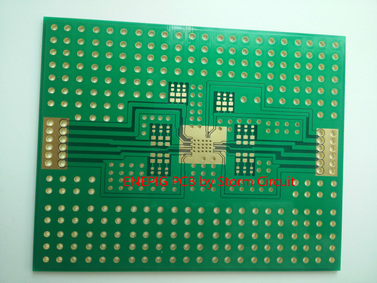

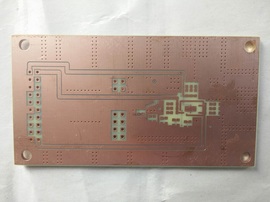

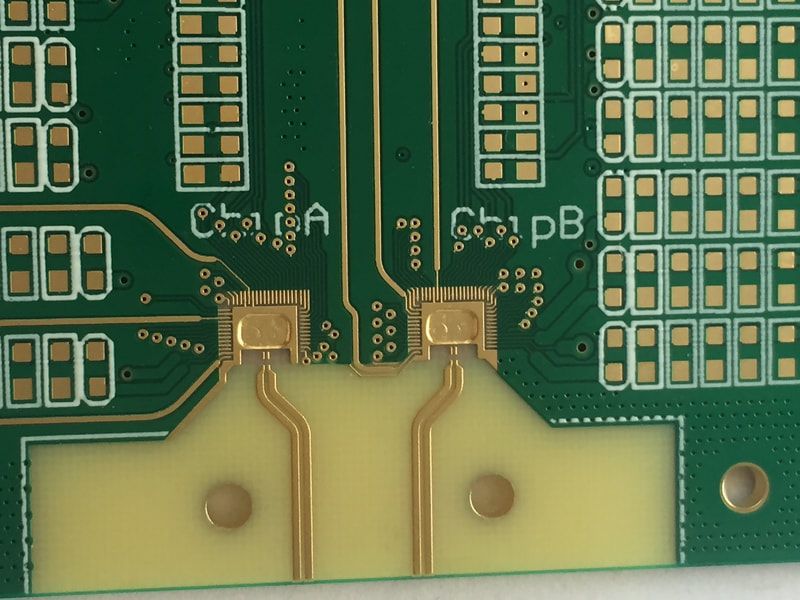

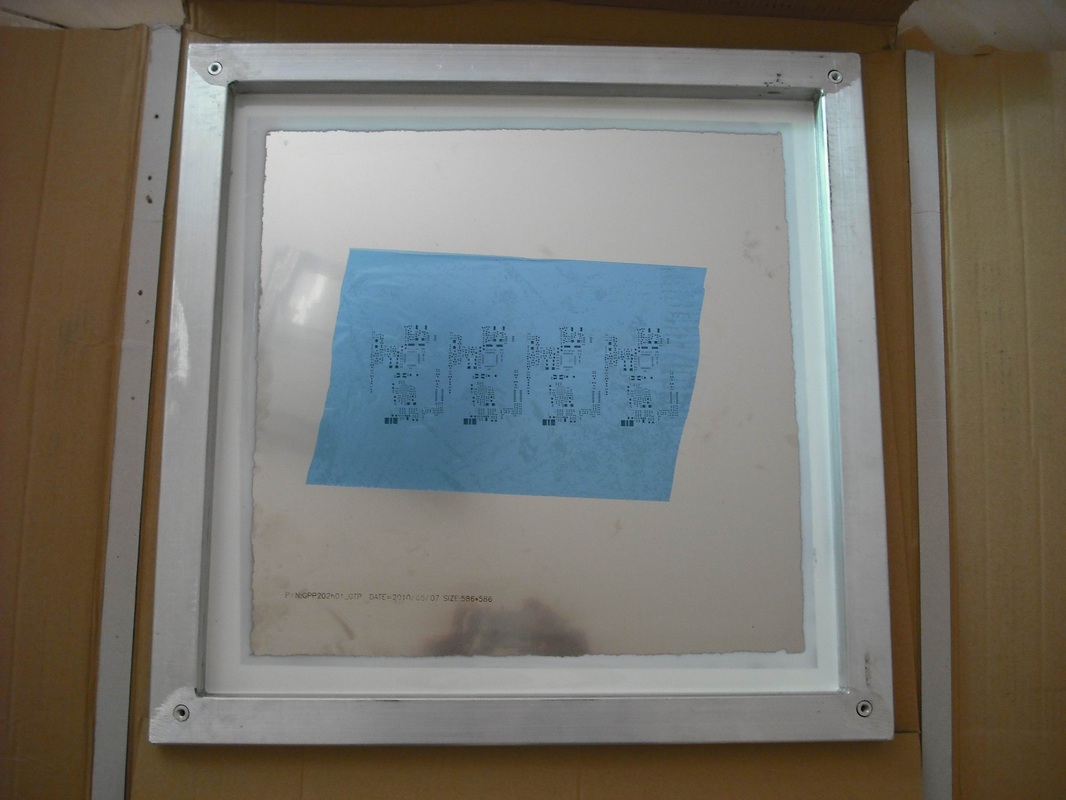

Here is an ENEPIG PCB ,60GHz Transceiver DC Board for Columbia University.

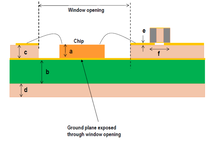

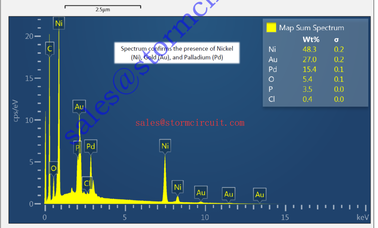

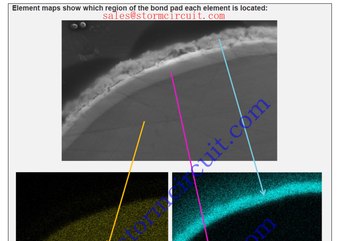

Thickness:Ni:3-5um +/-5%, Pd:0.1um +/-10%, Au:0.05um +/-10% Comparison of Surface Finish Performance

|

Download

Mullilayer standard stack up PCB Fab check list PCB capability Sample BOM Flex PCB material High frequency material |

|

|