How to save cost and make easily for your HDI PCB?

|

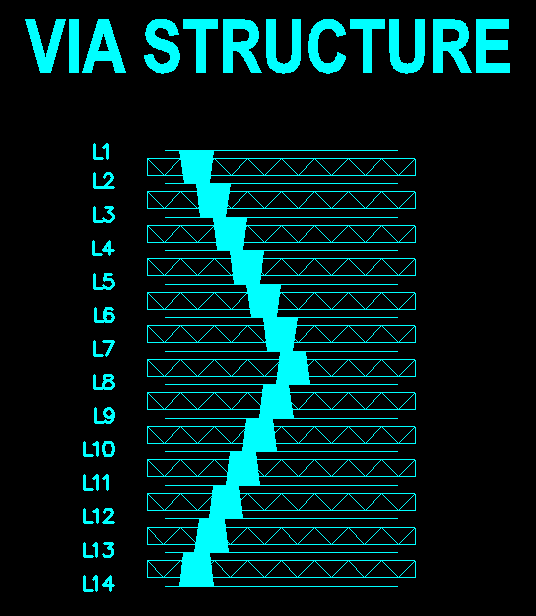

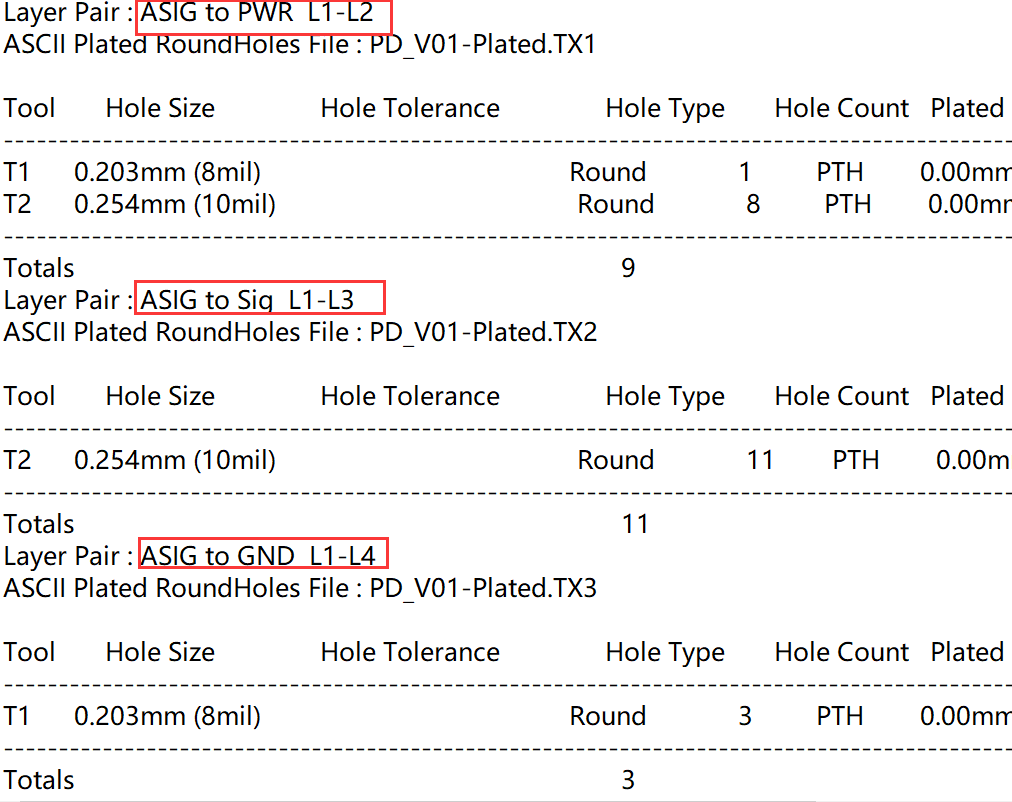

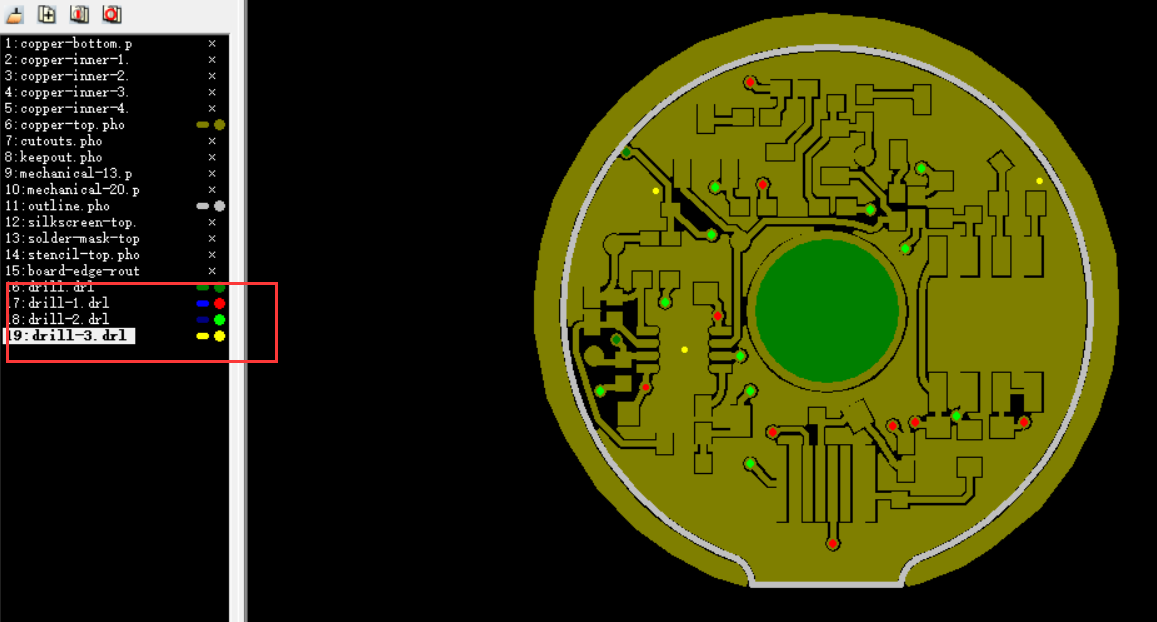

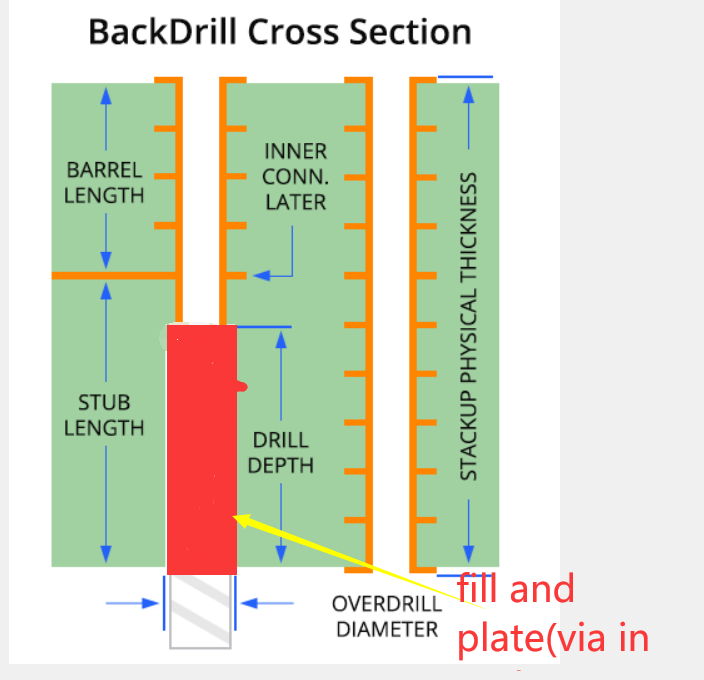

We have many customers sent us HDI PCB file ,but the files are very complex and high cost to do .some PCB designers do not have much experience in the PCB manufaturing,some files are unable to do .We--Storm Circuit has over 15 years experience in PCB fabrication and assembly. Our engineers have enough experience to optimize your HDI PCB. Here is an example. This is a 6 layer PCB ,Rogers 4003,Blind vias ( 0.25mm)from L1-L2,L1-L3,L1-L4, thickness is 1.6mm. So,how to do ?The key issue for PCB manufacturer is the blind vias. L1-L2 and L1-L4 is OK,no problem to do , The board must be done like an 8 layer with three cores (L1/L2,L3/L4,L5/L6).The stackup must be done with laser drilling for L1-L2 L1-L3,L1-L4. So blind vias will be changed from 0.25mm to 0.1mm. Customer does not agree. OK, then the next problem is drill 1-3 is too difficult for Rogers material , even many PCB factories can not make Rogers material with blind/buried vias. Rogers material is different as FR4 material. This design must be Rogers material ,it is a high frequency application. FR4 material is unacceptable to do ,and laser drilling is unacceptable too. There is another way? Our senior PCB engineer Kim Chan who has over 17 years experience in PCB manufacturing adviced to use back-drill and via in pad technology. That is 1-2 is a core, drill as usual , and 1-3 1-4 will be drilled as through holes first.Then, in the last process, we will drill out the copper for 3-6 /4-6,this is back-drill.But we will see holes at bottom side, it is different with the customer's design. Then ,we will fill and plate the back drill holes,so nothing we can see. This processs cost is a bit lower than FR4 with 1-2 1-3 1-4, and easy to do . Any layer HDI prototypes will be at least US$2000,but we used back drill and via in pad,cost cut down more than 30%. Of course, we confirmed with customer and get his approval to proceed. Rogers material with blind/buried vias ,we can do! If you have any HDI inquiries, please email to us directly. We can make any layer HDI for 14 Layers,like below structure .

Our any layer HDI partner is Foxconn,one of the top PCB manufacturers in the world. |

8 Layer HDI,

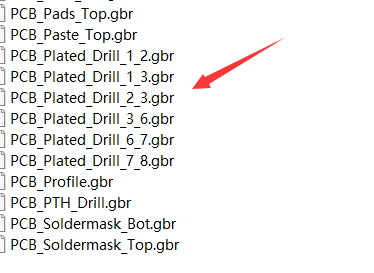

drill 1-2 drill 2-3 drill 3-6 drill 6-7 drill 7-8 min via 0.1mm, min trace/space 0.076/0.076mm |

Storm Circuit offer quick turn HDI PCB from 5 days to 20 days. the above 8 layer HDI ,we sent out in 6 days with quick turn service.