HDI-HIGH DENSITY INTERCONNECT PCB

|

|

HDI,1+N+1, Standard and quick turn lead time for prototypes. (<1 sq meter).

2+N+2 ,3+N+3. PCB gerber file is required to get correct cost and lead time |

|

Any layer/ELIC (every layer interconnection) is the most complex PCB to do.We made a few of such prototype PCBs.

|

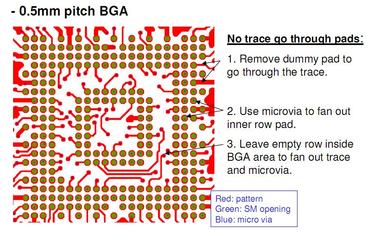

0.5mm pitch BGA design guide--NO trace go through BGA pads

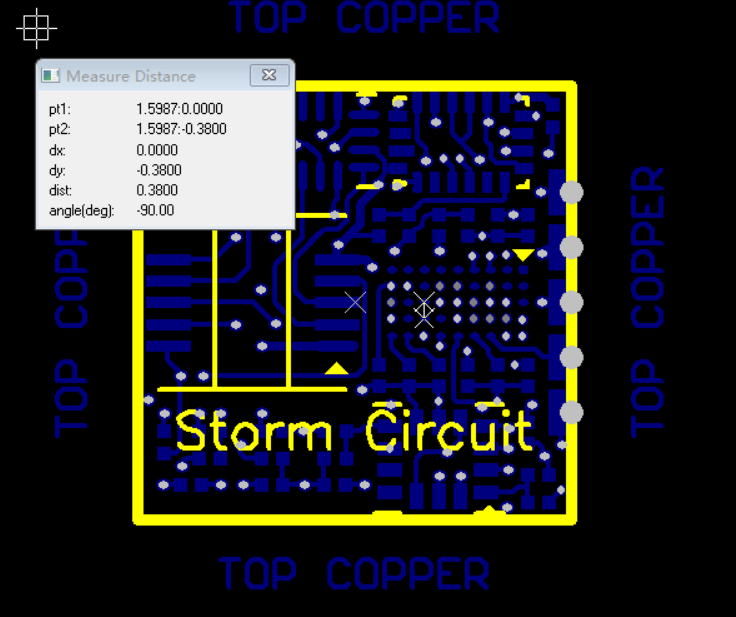

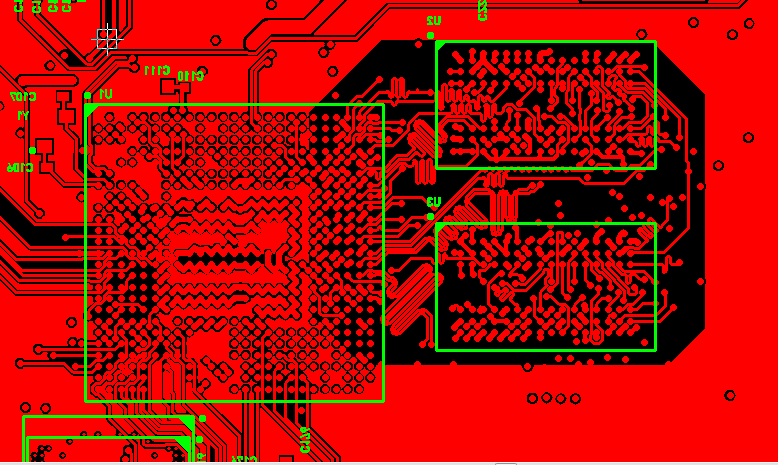

Gerber file for 6 layer HDI board.

Specification:FR4,TG170,1.2mm,1oz for all layers. min via:0.15mm, min trace/space:0.1/0.1mm. Impedance control,Black solder mask,ENIG Blind/burried vias (L1-L2,L1-L3,L4-L6,L5-L6) |

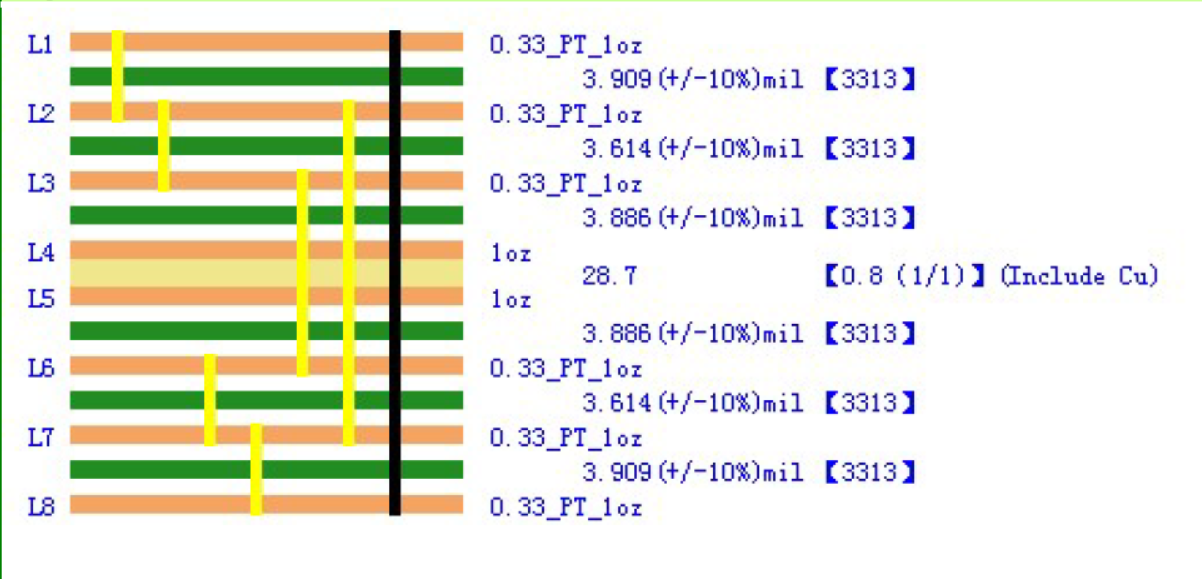

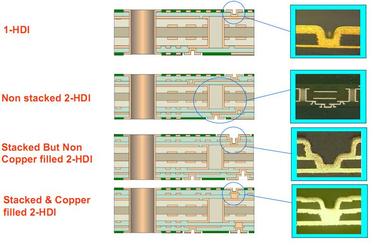

Examples of HDI stack up

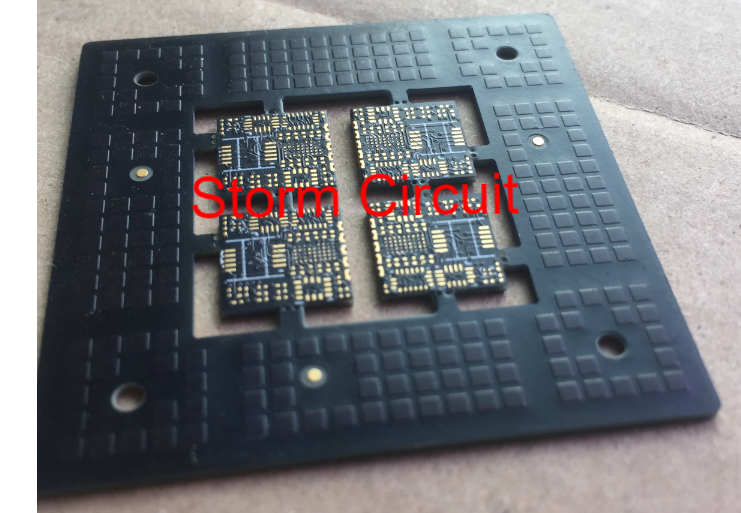

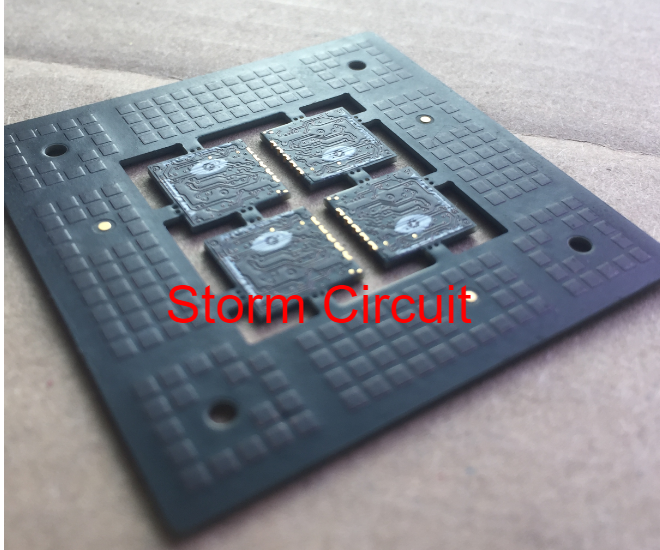

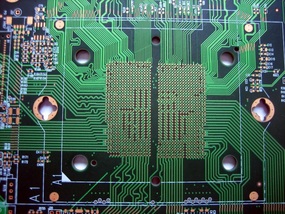

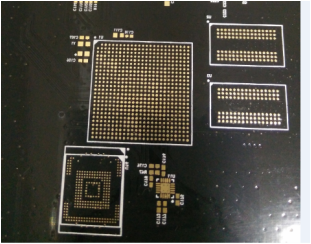

Real Board for the left Gerber.

|

Download

Multilayer standard stack up

PCB Fab check list

PCB capability

Sample BOM

Flex PCB material

High frequency material

Multilayer standard stack up

PCB Fab check list

PCB capability

Sample BOM

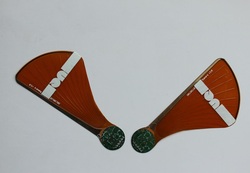

Flex PCB material

High frequency material