MC PCB--Metal Core Printed Circuit BoardsMC PCB means metal core printed circuit boards. why use metal,not FR4/CEM-1 or others? All is to get high thermal conductivity. The most MC PCB is Aluminum PCB, Aluminum has good heat transfer and dissipation ability, but also cheaper than copper based PCB.Many customers asked a quote for MC PCB but without the thermal requirements.If you know the thermal conductivity is the most most important thing for MC PCB,then

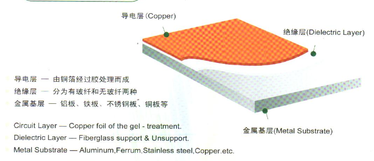

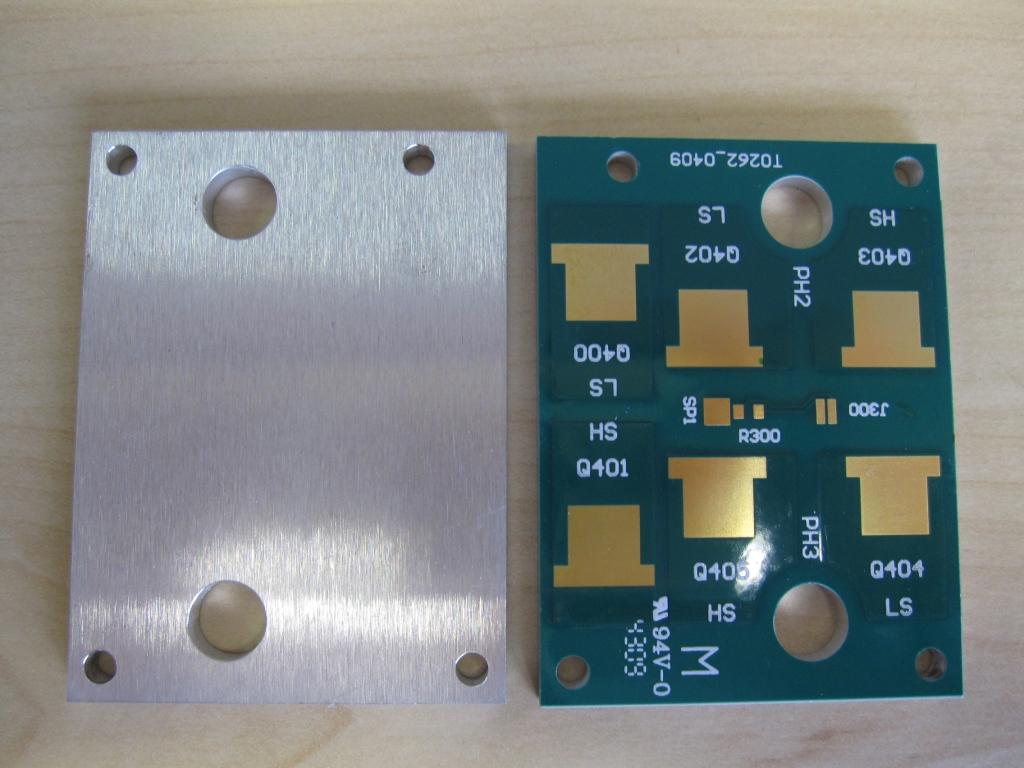

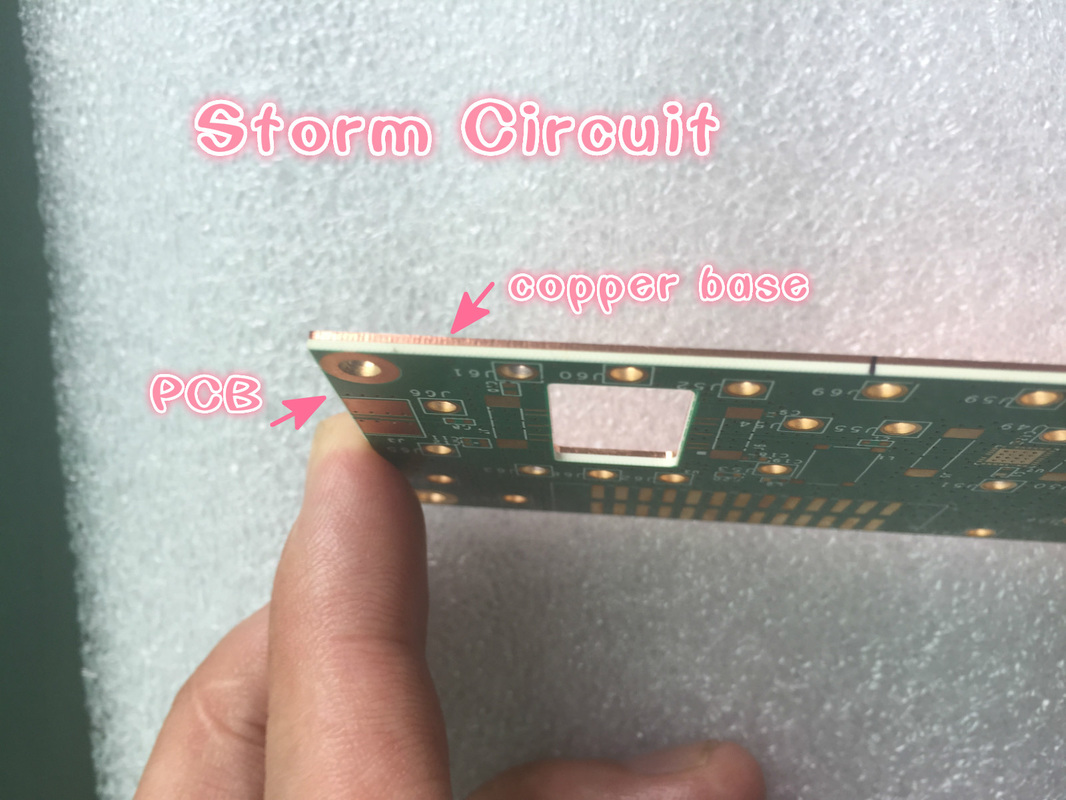

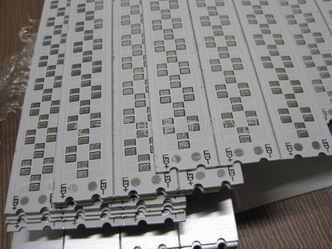

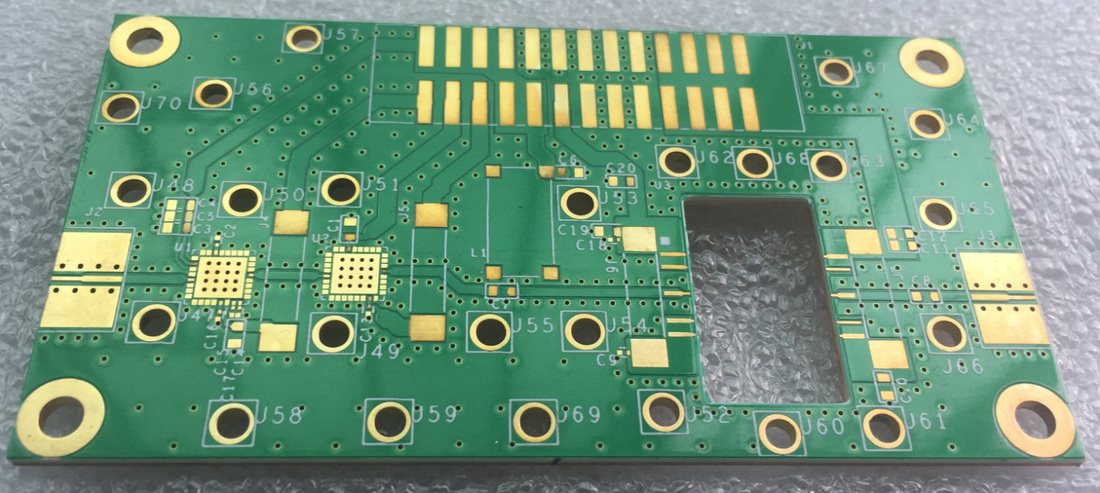

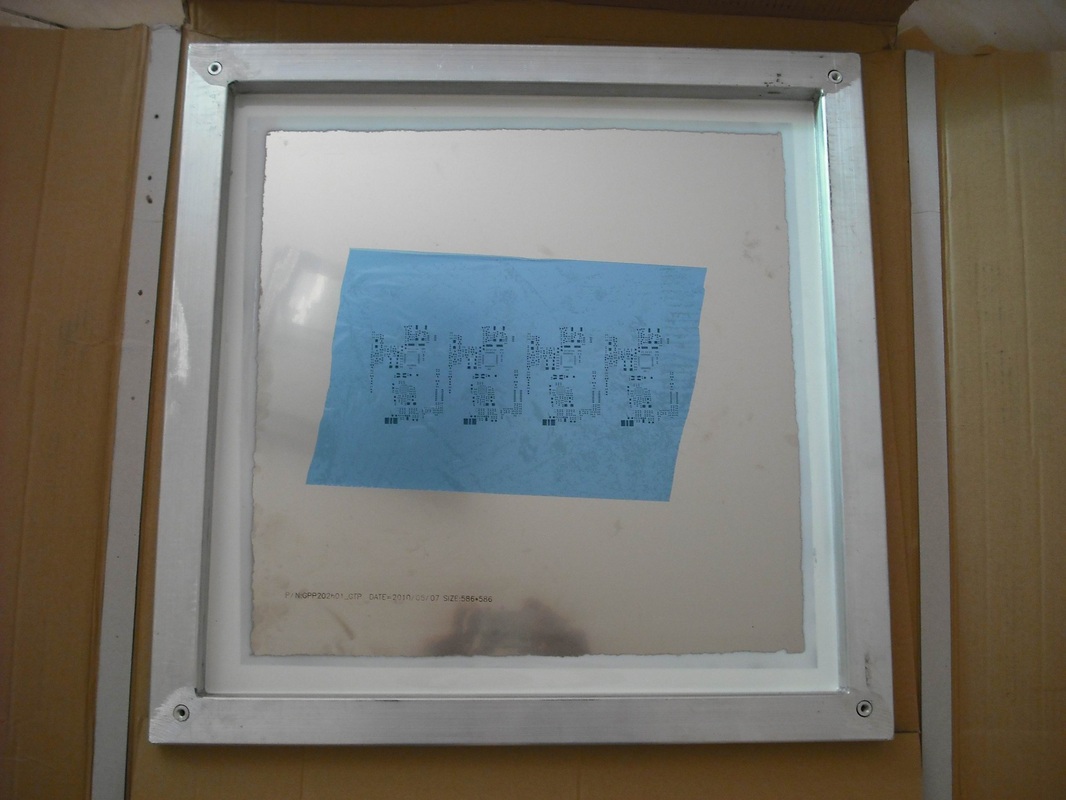

you will know why the price is so difference. Normal thermal is from 0.8-2.00 W/m.k,and higher can up to 8.0 W/m.k,even more if you need ,but ,are you sure ? When we quote to you ,we have to ask you the thermal conductivity,it is not only about cost but your product.Many factories used low thermal ,can you use the boards? MC PCB uses in LED lights,Industrial power equipment,Cars,Power,etc. Bergquist is the top quality metal core material but top cost as well. Thermal Conductive Board (TCB), or Insulated Metal Substrate (IMS), provides the advantages of high thermal conductivity, reliability and solder heat endurance. The TCB substrate is a sandwich structure, which includes layers of conductor, insulator and metal base.Traditionally, this insulator is made of epoxy, epoxy filled glass fiber, polyimide, or other dielectric materials. However, these kinds of insulators could not meet the requirement in high-power electronic devices. The heat generated by these devices will accumulate, and the life time and reliability of the end product will decrease. Visit bergquist to get more information about high thermal. PTTC (Polytronics) is another top quality but much cheaper than Bergquist in the word ,it is made in TaiWan .visit PTTC. In some countries,they call MC PCB as IMS PCB.IMS is Insulated Metal Substrates.Most is Aluminum as well. Copper based PCB is one tyepe of MC PCB ,it means the base (core)material is copper.See above .it is much difference than normal PCBs.also,the cost is a bit higher than FR4.

Copper has high conductivity,so this type PCB are used in many of high power applications,such as,LED,Power suppliers,Industrial. |

Download

Mullilayer standard stack up PCB Fab check list PCB capability Sample BOM Flex PCB material High frequency material |

|

|