PCB Panelization

|

A good panelization can save time and cost for customers and us too.

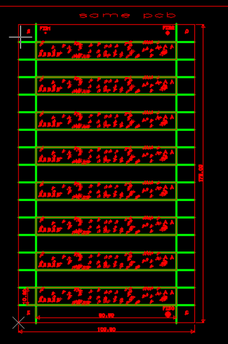

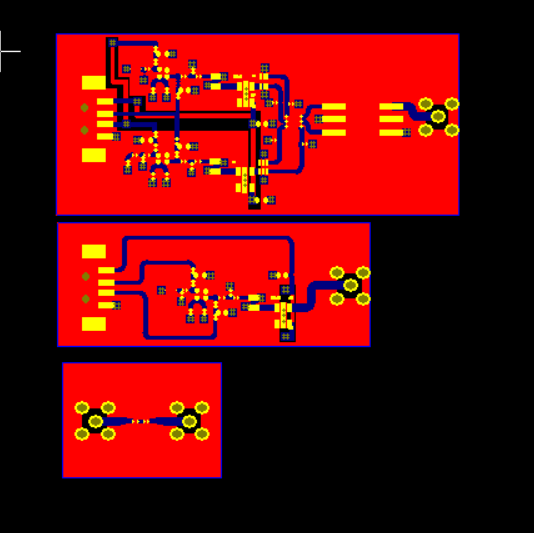

What is good panelization? There are two types. The first is the same PCB panelize in one sheet,see the right side. To assemble quicker ,we will add four board edges with 10mm, and three fiducial (not four), and four tooling holes at the edges. we will score the boards ,you can break them easily. Same PCB panelization is easy,we just need to copy and paste . If you panelization them by yourself,please note the board edges and space. Please email to sales@stormcircuit.com , if you have any PCB questions. |

|

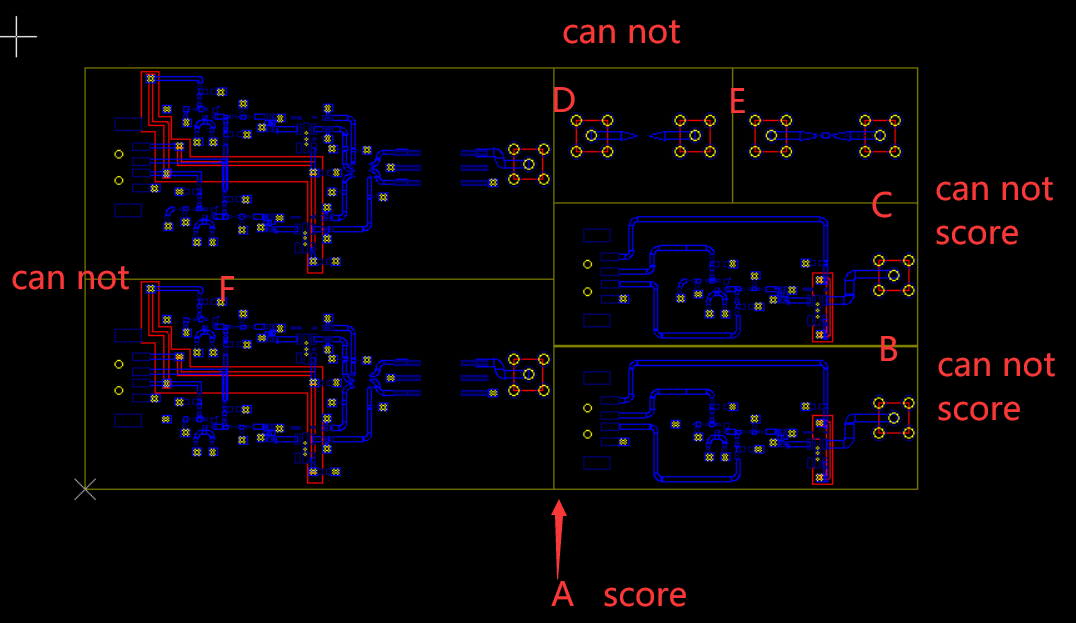

The second panelization type is the different PCB fit in one sheet.

Many design customers would like to make some prototypes, and there are some different PCBs in one sheet. But a lot of the customers made wrong panelization. That makes our engineer hard to do . see the left side. There are three different designs ,two of each in the panel. But we can not make it as per the panel drawing. We only can score (v-cut) the panel from A line,we can not score panels from the other lines .(B,C,D,E) it will damage another board when score. That makes you can not break them when you get the panel. Our engineers have to move the boards to get a space to rout or score. This is the panel we have to change. we can make more boards to you ,but the score lines have to be a vertical or horizontal straight line. or we will add 2mm space between each board.

Panelization tips

|